Top Picks: Laser Cutter Machine for Metal Engraving at Home

Welcome to the world of precision craftsmanship! If you’re a hobbyist, an artist, or even a small-scale manufacturer, a laser cutter machine for metal can open up a whole new realm of possibilities. These machines are not just tools; they’re powerful instruments that allow you to etch intricate designs, cut precise shapes, and create custom pieces with ease. Whether you’re working on jewelry, decorative items, or industrial parts, a laser cutter machine for metal is an investment worth considering.

In this article, we’ll explore everything you need to know about laser cutter machines for metal, their benefits, features, and how they can transform your creative projects. We’ll also address common questions and provide tips on choosing the right machine for your needs. Let’s dive in!

Why Choose a Laser Cutter Machine for Metal?

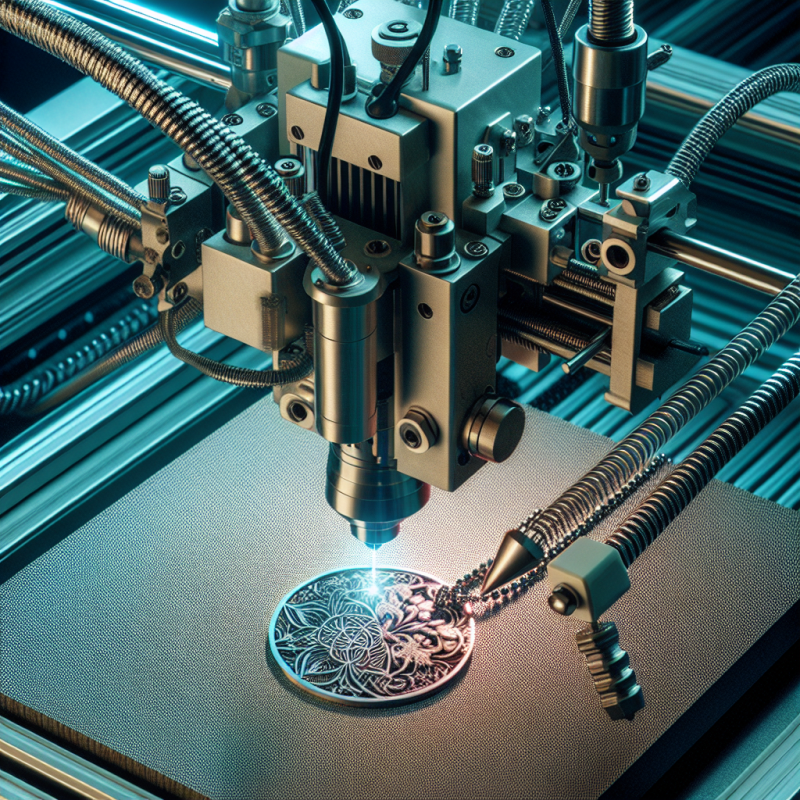

Laser cutting technology has revolutionized metalworking by offering unparalleled precision, speed, and versatility. Unlike traditional methods that require manual cutting or expensive tools, a laser cutter machine for metal uses focused light beams to melt, burn, or vaporize materials with pinpoint accuracy. This makes it ideal for creating complex designs, patterns, and cuts that would be nearly impossible with conventional tools.

Here are some of the key benefits of using a laser cutter machine for metal:

- Precision: Laser cutters can achieve tolerances as small as 0.1 millimeters, ensuring your designs are exact and professional-looking.

- Versatility: These machines work with a wide range of materials, including steel, stainless steel, aluminum, brass, and copper. They’re also compatible with non-metallic materials like wood, plastic, and glass.

- Speed: Laser cutting is much faster than manual methods, saving you time while maintaining high-quality results.

- Cost-Effective: With no need for expensive blades or tools, laser cutters reduce long-term costs and minimize waste.

Key Features of a Laser Cutter Machine for Metal

When selecting a laser cutter machine for metal, there are several features to consider:

- Laser Power: Higher wattage lasers can handle thicker materials, making them suitable for industrial applications. For home use, lower wattage machines (e.g., 30-60W) are often sufficient.

- Cutting Area: The size of the work area determines how large your projects can be. Look for machines with a cutting area that matches your needs.

- Software Compatibility: Many laser cutters come with user-friendly software for designing and controlling the machine. Ensure the software supports your operating system and design tools.

- Air Assist System: This feature improves cutting efficiency by blowing away molten material, resulting in cleaner cuts and reduced wear on the laser tube.

For those looking for a reliable option, the is an excellent choice. It’s designed for home use but delivers professional-grade results.

Applications of a Laser Cutter Machine for Metal

The versatility of a laser cutter machine for metal makes it suitable for a wide range of applications:

- Jewelry Making: Create custom rings, pendants, and other intricate pieces with ease.

- Decorative Metalwork: Engrave signs, plaques, and decorative items for a polished finish.

- Prototyping: Rapidly produce prototypes of components for testing and development.

- Industrial Manufacturing: Cut precision parts for machinery, automotive, or aerospace applications.

Frequently Asked Questions About Laser Cutter Machines for Metal

If you’re new to laser cutting, you might have some questions. Let’s address the most common ones:

- Q: Are laser cutter machines safe?

A: Yes, when used correctly and with proper safety precautions (e.g., wearing protective eyewear), laser cutters are safe. Always follow the manufacturer’s guidelines for operation. - Q: Can I use a laser cutter machine for thick metals?

A: It depends on the laser power and type. Higher wattage machines can handle thicker materials, but for most home users, thinner metals are more practical. - Q: Do I need special training to use a laser cutter machine?

A: Basic knowledge of computer-aided design (CAD) software and machine operation is helpful. Many machines come with tutorials or user guides to get you started.

Maintenance Tips for Your Laser Cutter Machine

To ensure your laser cutter machine for metal stays in top condition, follow these maintenance tips:

- Clean the work area regularly to remove dust and debris.

- Check and replace the laser tube or mirrors as needed to maintain performance.

- Use compressed air to blow away residue after cutting to prevent buildup.

- Store the machine in a dry, cool place when not in use to protect it from humidity and dust.

Conclusion

A laser cutter machine for metal is an invaluable tool for anyone looking to take their craftsmanship to the next level. With its precision, versatility, and speed, it’s no wonder that laser cutting has become a go-to method for both hobbyists and professionals alike.

If you’re ready to invest in a high-quality machine, consider checking out the laser cutter machine for metal. It’s perfect for home use but offers the performance of industrial-grade equipment. Happy creating!